Featured Products

-

Professional China High-End PDC Cutter Insert Tungsten Carbide Substrate Carbide & Diamond Material For Diamond Drill Bit Geological Drilling Bits

PDC is divided into main size series such as 19mm, 16mm, and 13mm according to different diameters, and auxiliary size series such as 10mm, 8mm, and 6mm. Generally, large-diameter PDCs require good impact resistance and are used in soft formations to achieve high ROP; small-diameter PDCs require strong wear resistance and are used in relatively hard formations to ensure service life.

The PDC produced by our company is mainly used as cutting teeth for oil drilling bits, and is used in oil and gas exploration and drilling and other fields. -

High definition PDC Rock Bit 17 Inch Diamond Fixed Cutter PDC Drill Bit of Downhole Drilling Tools

According to different diameters, PDC is divided into main size series such as 19mm, 16mm, 13mm, etc., and auxiliary size series such as 10mm, 8mm, and 6mm. Generally, large-diameter PDCs require good impact resistance and are used in soft formations to achieve high ROP; small-diameter PDCs require strong wear resistance and are used in relatively hard formations to ensure service life.

We can accept customer customization or drawing processing. -

Drilling Tool Rock Drill Bit Tricone Bit Oil Drill Bit Mt TCI Tungsten Carbide Cone Bit

The company mainly produces two types of products: polycrystalline diamond composite sheet and diamond composite tooth. The products are mainly used in oil and gas drill bits and mining geological engineering drilling tools.

Diamond tapered composite teeth have extremely high wear resistance and impact resistance, and are highly destructive to rock formations. On PDC drill bits, they can play an auxiliary role in fracturing formations, and can also improve the stability of drill bits. -

Factory wholesale PDC cutter for Chain saw/marble quarry/oil / gas / coal drilling/0808 1004 1008 1304 1308 1313 1908 1913 PDC Insert cutter

The company can now produce non-planar composite sheets with different shapes and specifications such as wedge type, triangular cone type (pyramid type), truncated cone type, triangular Mercedes-Benz type, and flat arc structure. The core technology of polycrystalline diamond composite sheet is adopted, and the surface structure is pressed and formed, which has a sharper cutting edge and better economy. It has been widely used in drilling and mining fields such as diamond bits, roller cone bits, mining bits, and crushing machinery. At the same time, it is especially suitable for specific functional parts of PDC drill bits, such as main/auxiliary teeth, main gauge teeth, second row teeth, etc., and is widely praised by domestic and foreign markets.

Diamond ridge teeth. Non-planar diamond composite sheet for oil and gas drilling, a special shape, forms the best cutting point to obtain the best rock drilling effect; it is conducive to eating into the formation, and has higher mud bag resistance. -

Factory source Big Size 12 1/4″ 311mm IADC537 637 Well Drilling TCI Tricone Bits for Hard Formations

Pyramid PDC Insert has sharper and lasting edge than Conical PDC Insert. This structure is conducive to eating into harder rock, promoting the rapid discharge of rock debris, reducing the forward resistance of PDC Insert, improving the rock breaking efficiency with less torque, keeping the bit stable when drilling. lt is mainly used for manufacturing oil and mining bits.

-

New Delivery for Round PDC Spherical Button on Tricone and PDC Bit

Wedge PDC Insert has better impact resistance than Plane PDC, sharper edge and better impact resistance than Conical PDC Insert. In the process of PDC bit drilling, the Wedge PDC Insert improves the “scraping” working mechanism of the plane PDC to “ploughing”.This structure is conducive to eating into harder rock, promoting the rapid discharge of rock debris, reducing the forward resistance of PDC Insert, improving the rock breaking efficiency with lesstorque. It is mainly used for manufacturing oil and mining bits.

-

Cheap price Hot Sale Mining DTH Hammer Button Bits Water Well Drilling PDC Bits

The company produces non-planar composite sheets with different shapes and specifications such as wedge type, triangular cone type (pyramid type), truncated cone type, triangular Mercedes-Benz type, flat arc structure, etc. The core technology of polycrystalline diamond composite sheet is adopted, and the surface structure is pressed and formed, which has a sharper cutting edge and better economy. It has been widely used in drilling and mining fields such as diamond bits, roller cone bits, mining bits, and crushing machinery. At the same time, it is especially suitable for specific functional parts of PDC drill bits, such as main/auxiliary teeth, main gauge teeth, and second row teeth.

-

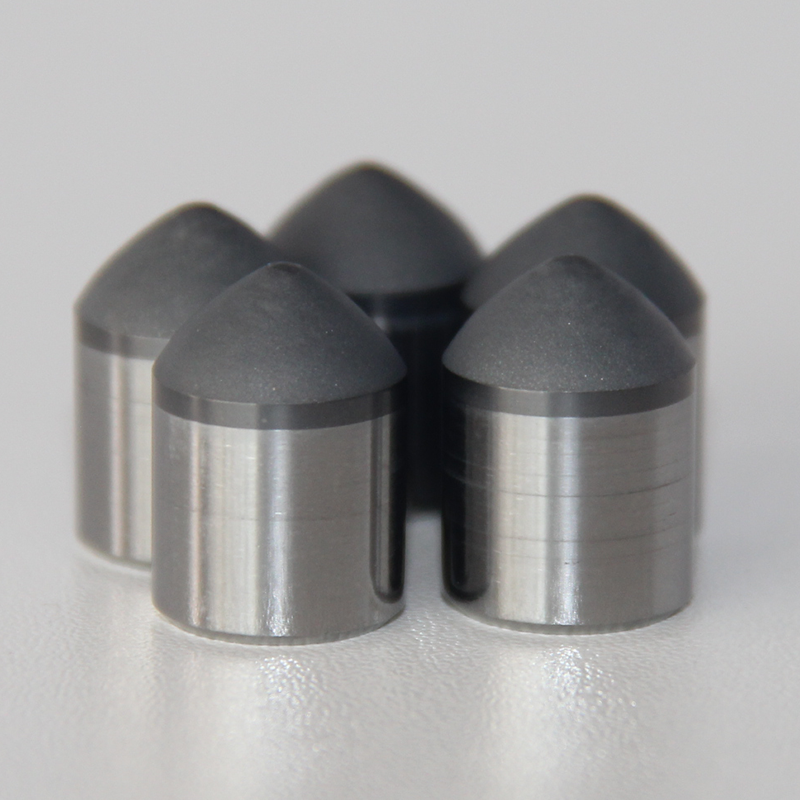

C1113 conical Diamond composite teeth

Diamond composite teeth (DEC) can be divided into: diamond composite conical teeth, diamond composite spherical teeth, diamond composite conical spherical teeth, diamond composite oval teeth, diamond composite wedge teeth, diamond composite flat-top teeth in terms of appearance and functional application. etc.

conical Diamond composite teeth have extremely high wear resistance and impact resistance, and are highly destructive to rock formations. On PDC drill bits, they can play an auxiliary role in fracturing formations, and can also improve the stability of drill bits.