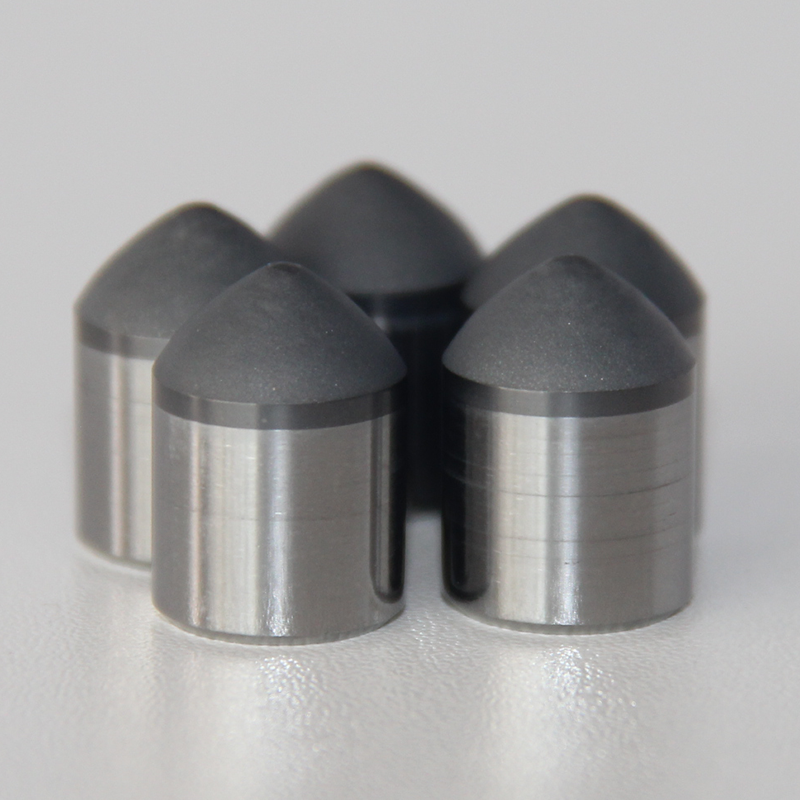

DW1214 diamond wedge composite teeth

| Product Model |

D Diameter | H Height | SR Radius of Dome | H Exposed Height |

| DW1214 | 12.500 | 14.000 | 40° | 6 |

| DW1318 | 13.440 | 18.000 | 40° | 5.46 |

Proudly launch DW1214 diamond wedge composite tooth, a revolutionary product that combines the core technology of polycrystalline diamond composite sheet and the surface structure of press molding. This results in a sharper cutting edge and greater economy, making it the first choice in drilling and mining.

DW1214 diamond wedge compound teeth have been used in a wide variety of applications including diamond bits, roller cone bits, mining bits and crushing machinery. It is especially suitable for specific functional parts such as main/auxiliary teeth, main gauge teeth, and second row teeth of PDC drill bits. Its excellent performance in these applications has won wide acclaim in domestic and foreign markets.

One of the main advantages of DW1214 diamond wedge composite teeth is their exceptional durability. It is able to withstand harsh drilling and mining conditions and maintain a cutting edge for longer. Not only does this increase the efficiency of these operations, it also helps reduce the number of replacements required, resulting in significant cost savings.

Another advantage of this product is its excellent performance in a range of different materials. Whether it’s hard rock or loose soil, the DW1214 diamond wedge compound teeth cut through these materials efficiently and easily. Its ability to handle a wide range of materials makes it a highly versatile product suitable for a variety of different drilling and mining applications.

So if you are in the market for a high quality cutting tool that is both durable and versatile, look no further than the DW1214 Diamond Wedge Compound Tooth. Its superior performance, affordability and ease of use make it the perfect choice for anyone in the drilling and mining industry. Order now and experience the difference for yourself!